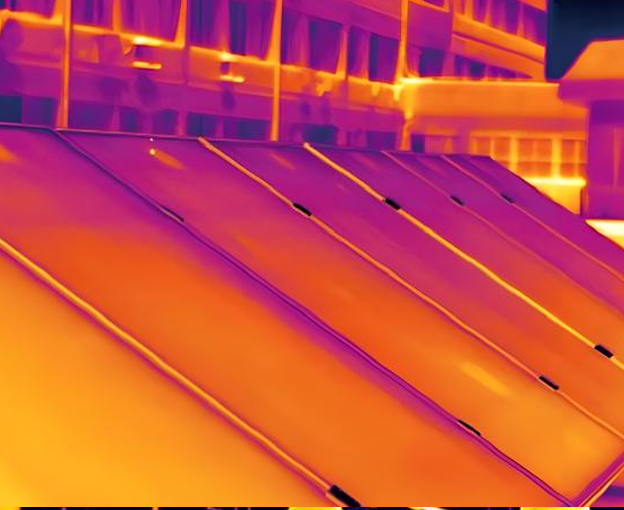

Thermal imaging has a wide range of applications in the power industry. The security of the power industry is very important; a little bit of hidden danger may cause incalculable losses. Therefore, daily inspection is especially important, and an infrared camera becomes the best helper.

1. Safe operation: non-contact detection, adapt to a variety of detection environments;

2. Efficient and fast: face measurement, without point-by-point scanning to improve the efficiency of the investigation;

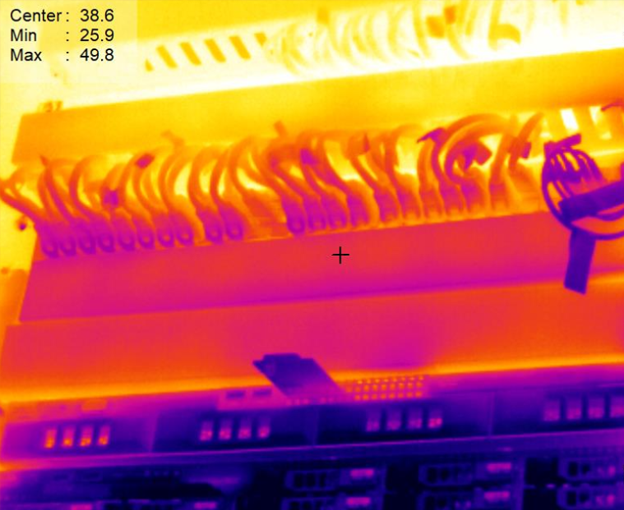

3. Comprehensive: visualization image shows the overall temperature distribution and real-time discovery of the problem point.

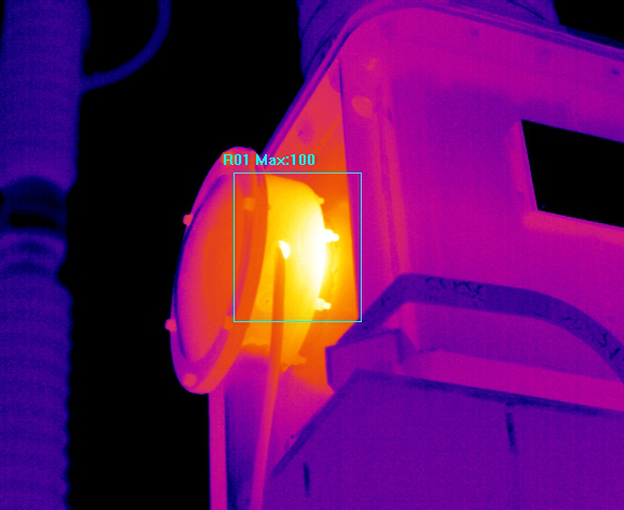

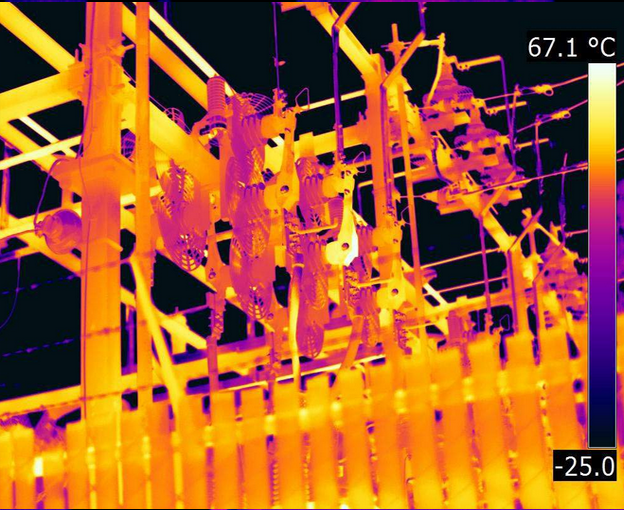

1. Power equipment inspection: transformers, capacitors, reactors, circuit breakers, insulator strings, generators, transformers, isolation switches, transmission wires, and crimp tubes.

2. Substation infrared inspection robot: The electrical thermal imaging camera replaces manual work to complete urgent, difficult, dangerous, and repetitive work in substation inspection. It adopts high-resolution infrared detectors and excellent temperature measurement performance. It transmits a real-time temperature map and data to the back-end monitoring. The electrical thermal imaging camera automatically judges and alarms the equipment's thermal defects.

3. Infrared inspection drone for power transmission lines: discovering the hidden fault points through the abnormal temperature change contrast value.