As a powerful tool for human understanding of the world, photoelectric imaging chip helps human to explore the world from molecular scale to planetary bodies and broaden the boundaries of human knowledge. Since Infrared and Ultraviolet spectra, which cannot be perceived by human eyes, were discovered, human beings have been fascinated with the exploration of the world beyond the visible spectrum. Whether it is shortwave infrared (1~2.5 μm) that can penetrate clouds or ultraviolet (<0.4 μm) that can stimulate fluorescence, people are always looking forward to witnessing the world under this magical spectrum with their own eyes through an excellent photodetector.

Although bulk semiconductor materials such as gallium nitride (GaN), indium antimonide (InSb), mercury cadmium telluride (HgCdTe) and class II superlattices can broaden the spectral detection range of CMOS detectors, such bulk semiconductor materials are not compatible with silicon-based CMOS detectors, and complex processes such as flip bonding are required in the processing process. Resulting in high cost and low pass rate of detector production process. At the same time, the energy of ultraviolet and infrared photon is very different, and cross-band and cross-band gap coupling is extremely difficult. The solution properties of colloidal quantum dot materials can be used to pattern quantum dot films by direct lithography after the quantum dot infrared material is coupled to the CMOS readout circuit, and the multi-band wide spectrum detector from ultraviolet to infrared can be made by plane coupling. By using lead sulfide (PbS) quantum dots, the team of Professor Tang Jiang of Huazhong University of Science and Technology realized the preparation of near infrared quantum dot chips, and demonstrated good imaging performance under 970nm infrared irradiation.

In order to break through the band bottleneck, Professor Xin Tang of Beijing Institute of Technology proposed the use of mercury telluride (HgTe) and perovskite colloidal quantum dot materials to broaden the detection range of CMOS, improve the detector manufacturing scale, achieve wafer-level processing, greatly reduce the detector production cost, improve the process pass rate. Since the band gap of the bulk material is zero, the colloidal quantum dots of mercury telluride (HgTe) can realize the preparation of short-wave infrared, medium-wave infrared and long-wave infrared detectors.

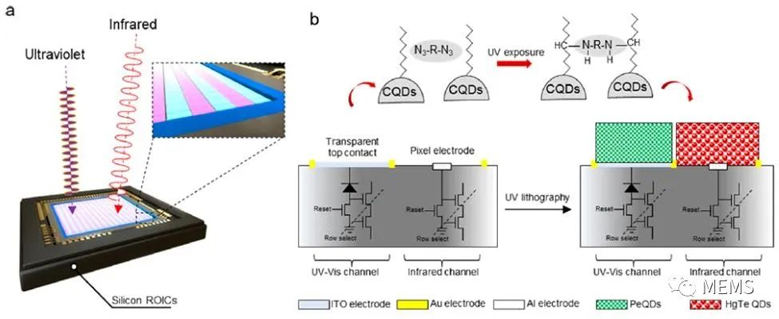

FIG. 1 a. Multi-band wide-spectrum detector layout; b. Ligand exchange process and structure diagram of ultraviolet pixel and infrared pixel.

The silicon-based readout circuit used by the multi-band wide spectrum detector is specially customized and designed for layout (FIG. 1.a). One channel is a pixel decorated with a transparent top electrode, which is used as a modified area of perovskite quantum dots to respond to the ultraviolet band signal to achieve the down-conversion process. The pixel channel can not only capture visible light, but also be applied to collect special information such as fingerprint recognition in ultraviolet scenes. The other channel uses a direct injection circuit as the pixel of the acquisition and amplification circuit, and modifies the infrared material of mercury telluride colloidal quantum dots in this area, which can capture the short-wave infrared signal of 1~ 2.5μm, and obtain the infrared characteristics of the object to identify the substance composition (Figure 1.b).

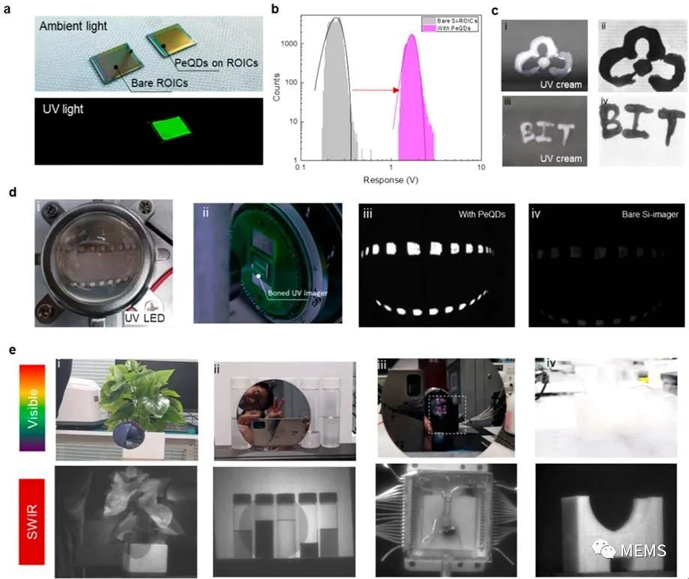

FIG. 2 Image of quantum dot detector in monochromatic mode. a. Photos of the detector under ambient light and ultraviolet light; b. Response distribution diagram of detector after reading circuit and perovskite quantum dots modification; c. Sunblock photo under ultraviolet irradiation; d. Visible and ultraviolet images: (i) ultraviolet LED photos, (ii) ultraviolet detector photos, (iii) detector detection photos modified perovskite quantum dots, (iv) readout circuit detection photos; e. Visible light images and short-wave infrared images taken by detectors modified with HgTe quantum dots.

Figure 2 shows the detection effect of a multispectral wide-spectrum quantum-dot detector made using this research method in monochromatic mode. As can be seen in FIG. 2.c, the sunscreen appears black under ultraviolet light, indicating that ultraviolet light is absorbed by the sunscreen. Therefore, the ultraviolet signal attenuation in the area where sunscreen is applied shows black, which also proves that the detection range of the detector in this mode is ultraviolet band. Figure 2.e shows four classic scenes in shortwave imaging. (i) (ii) (iii) shows that shortwave infrared can penetrate silicon wafers, because the absorption wavelength of silicon wafers is up to 1.1 μm, while the detection range of HgTe quantum dots used by quantum dot detectors is 1~2.5 μm, so the silicon wafers appear transparent in this detection range. A classic shortwave infrared application scenario is also shown in (ii), which is used to distinguish the components of chemical drugs. In the HF infrared detection mode, the transparent chemicals (from left to right: chlorobenzene, ethanol, chloroform, water, butyl acetate) appear in different shades of gray in the image due to the different absorption strengths of the short wave due to the chemical bonds they contain. (iv) shows the unique ability of shortwave to penetrate clouds and fog.

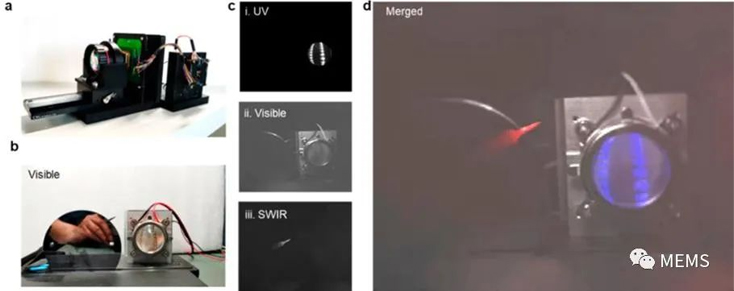

FIG. 3 Multi-spectral wide-spectrum quantum dot detector and its detection image. a. Multispectral wide spectrum quantum dot detector module; b. Imaging scene (including soldering iron, silicon wafer and UV lamp); c. Ultraviolet images, visible images and infrared images acquired; d. Collected information fusion image (red channel for short-wave infrared information, blue channel for ultraviolet information, gray channel for visible light information).

Figure 3 shows the use of a multi-spectral wide-spectrum quantum dot detector to image the scene containing a 580℃ electric soldering iron, silicon wafer and UV lamp. It can be seen that the ultraviolet, visible light and short-wave infrared information characteristics (short-wave infrared information released by the soldering iron that can penetrate the silicon wafer, ultraviolet light information released by the ultraviolet LED, visible light information of the wire and ultraviolet LED module) can be obtained by using a multi-spectral wide spectrum quantum dot detector module. Through the fusion of images, spectral information photos from ultraviolet to shortwave infrared can be displayed, providing more scene details.

The breakthrough in this research can greatly simplify the complexity of optical hardware and software of multi-band cameras, reduce the size and weight of cameras, and help realize the micro-miniature platform design of multi-band cameras. The team used direct lithography to realize the idea of colloid quantum dots to achieve two-color or multi-color focal plane arrays, breaking through the traditional block semiconductor material flip bonding process to complete the multi-color detection and coupling of the detector, realizing multi-band detection and multi-color imaging capabilities in one detector, greatly reducing the production cost of multi-color detectors and improving the production process scale and product pass rate. At the same time, this work has been strongly supported by SMIC Thermal Forming Technology (Beijing) Co., LTD. (hereinafter referred to as "SMIC Thermal forming") in the preparation of focal plane detectors and the testing of focal plane imaging systems. As the first high-tech enterprise in China focusing on infrared quantum material imaging chips, SMIC focuses on the preparation and packaging technology of new infrared quantum material devices, and launches the next generation of low-cost, high-resolution short-wave and medium-wave infrared imaging chip solutions around low-dimensional quantum materials, breaking through the traditional semiconductor flip bonding process. It carries out the packaging and testing business of low-cost silicon-based readout circuit on-chip integrated infrared chips. At present, the research and development work of short-wave infrared and medium-wave infrared isofocal plane arrays of 320×256, 640×512, 1280×1024 arrays has been successfully developed, and it has batch production line design and production capacity.